Agriculture Machinery

Serving OEM Partners Worldwide

Industries We Serve

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

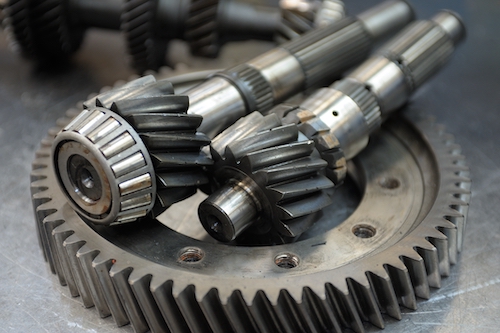

Power Take Off Units: Components and Bearings

If you produce tractors and their related components, you’re not alone. Worldwide, two million tractors are sold every year. And it’s no wonder why; tractors are one of the most important pieces of machinery for farming. Overlooking key aspects of your application, especially at the level of the power take off unit, can be the difference between successful yields for your customers and mid-season breakdowns that cause them to browse other brands.

The multi-faceted nature of tractors makes them very useful, but their performance is only as good as their reliability. That’s why the ever-integral bearing deserves a close and analytical look.

This article will walk you through all you need to know about the role and purpose of the bearings within every tractor’s power take off unit.

What Is a Power Take Off Unit?

A power take off (PTO) is a gearbox with seals, bearings, and other moving parts that transfers an engine’s mechanical power to another piece of equipment that does not have its own engine or motor. This power transfer applies to a secondary shaft that drives a hydraulic pump, generator, air compressor, pneumatic blower, or vacuum pump.

PTOs and the bearings within them should be able to support high radial loads.

In the world of agriculture, equipment powered by power take offs typically include tillage machinery, seeding and planting machinery, and mowing equipment. If there is any sort of shaft rotation required for machinery but it is without dedicated power, you can safely bet the machinery is intended to be powered by a PTO.

The Physical Influence of Bearings in PTOs:

Selection of a power take off requires specific information relating to the application and the power needs of the secondary or driven component. In this same way, the bearings within the PTO deserve to be considered.

Bearings in power take off units are subject to a myriad of forces. Quality bearings are made with the demands of specific PTO requirements such as:

- Torque and horsepower requirements of the driven component

- Intermittent or continuous operation

- Application usage

- Speed requirements of the driven component

- Mounting face dimensions and options

- Space allocation

- Amount of radial load

Overall Bearing Life

We here at WD source 99.98% VIM-VAR steel for our bearings. Why? Because material quality is one of the most important components to maximizing bearing lifetimes. Bearings worth being in your PTO require high-quality steel to improve upon bearing fatigue and improves operation performance.

Product Consistency

Quality creates value. Period. Consistent manufacturing, ball and roller selection, and quality control management is often overlooked when choosing bearings to create reliable machines. When a product is the same with every order, expectations can be met confidently. Consistent manufacturing processes and suppliers allow for machinery OEMs to be confident in their applications operating as intended day-after-day.

Fracture Resistance

Usually, the power take off unit of a tractor will be rigged up to a hydraulic system. Hydraulic machinery uses the transference of fluids to power the gearbox. Your PTO will often be hooked up to a hydraulic pump, transmission, or other electronic device so it can transfer fluids to the machinery you’ve attached. This transfer of power can fracture bearings. Our bearings are outfitted with robust retainers, large rivets, and more to resist damage during vibration.

Axial Load and Misalignment Capacity

As stated earlier, your PTO is a type of drive-shaft, an important piece of most commercial vehicles. They are used to provide mechanical torque and rotation. Naturally, bearings in PTOs need to have a high tolerance to both radial and axial loads. We optimize our bearings to maximize their strength through ideas like customizing shoulder heights or cage design. Customizing bearings is one way we have established ourselves in the industry.

The Social Influence of Bearings in PTOs:

It is paramount to the successful operation of any OEM of power take off equipment to carefully consider the bearings they choose. When generating motion is the method of distributing power, what does it say when bearings are overlooked? In many ways the decisions made with bearings influence the overall performance and lifetime of power take offs affecting customer relationships, revenue, and perception of brand.

The bearings within PTOs, like other components,, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

We have a robust selection of roller and radial bearings such as tapered roller bearings, angular contact roller bearings, and deep groove ball bearings.

Get the Most Out of Your Bearings

As an OEM, you need reliable bearings in the machinery you create.

Power take off units are everywhere. And those in the agriculture industry know the difference between quality craftsmanship and poorly-made scrap. Understanding the crucial relationship between quality bearing components and PTO performance pays dividends for both you and your customers.

For more information or to order our services, contact us today.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.