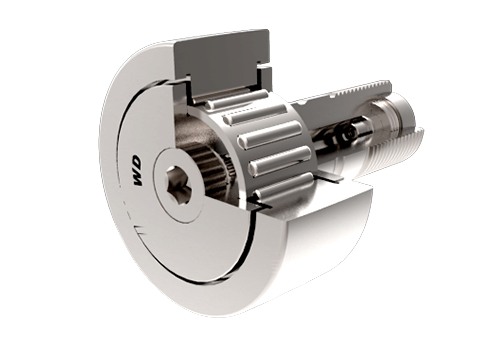

Cam Followers

Designed to maximize preferred motion with rigid, consistent construction. Cam followers feature a simple and low friction profile to transform rotary motion into linear motion with low lubrication requirements.

The WD Edge:

- Standard and custom options including sizes, materials, and designs

- Optimized raceways for improved contact stress distribution

- Higher clearance tolerances than industry standards

- High precision flexibility for different applications

- Maintenance-free with grease for life

- Variable cages, shields, seals, and outer ring designs

- Available as mini, standard, eccentric, and with thrust disks

- Simple installation using sockets or screwdrivers

Rigid, Accurate, and Clean Cam Followers

Simple Construction wit Rugged Designs

Cam followers from WD Bearing Group are ready-to-mount units complete with grease. They are suitable for all types of cam drives, tracks, conveyor systems, and more. The internal designs and external dimensions are completely customizable with standard catalog options available, too.

Quick Links

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

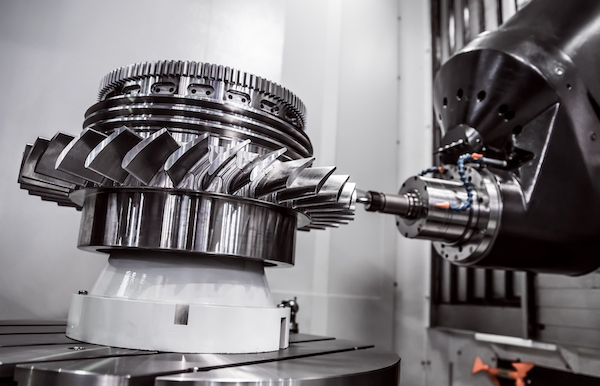

Cam Followers: Components and Uses

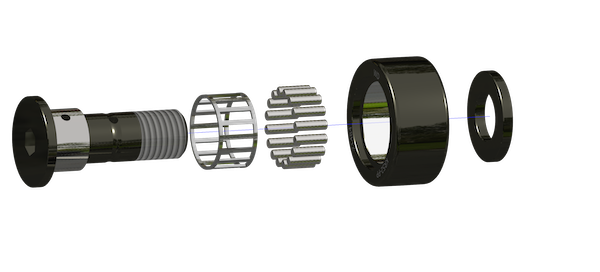

Cam followers are a type of bearing which transfers motion from one component to another by converting rotary motion into linear motion. They are robust and able to withstand intermittent shock and heavy loads while supporting lateral or vertical movem ent. Cam followers also reduce sliding friction and wear between independently moving machine sections, cams, or tracks. Cam followers are often called track rollers . Typically made as a roller or needle bearing, these bearings are designed to follow predefined profiles.

WD Bearing Group manufactures both catalog and customized cam followers from 20mm stud to 200 mm outside diameter sizes. Where other manufacturers have become rigid, WD has continued to provide quality cam followers to OEM’s worldwide. Reach out to the WD engineering and sales teams to learn why more manufacturers are switching to WD-manufactured cam followers .

Types of Cam Followers

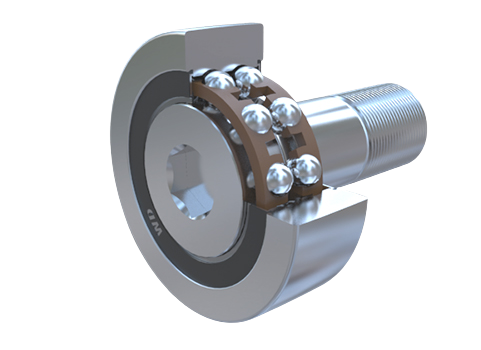

Stud Type

Stud type cam followers utilize a stud to mount the bearing to machinery. Hex sockets are commonly seen for applications requiring higher torque like eccentric cam followers. The tradeoff for the higher torque, of course, is the inability to lubricate any cam followers on the end with the hex socket. Eccentric studs are available for WD cam followers and offer a wide adjustment range during installation. Stud-type cam follower shafts are partially threaded for direct install or can be fastened with a nut.

Yoke Type

Yoke type cam followers are mounted through a hole in the center like traditional bearings. Yoke type followers typically offer greater load capabilities given the load is more evenly distributed when compared to stud type followers.

Our friends at COMSOL have a robust library of cam follower animations for you to view complete with variants and an outstanding level of technical rigor.

Conveyors

Material Handling

CNC

Components

Outer Raceway

Cam followers feature an outer raceway that is loaded at a single point which requires a more robust cross-section in order to prevent deformation. This represents a major difference to traditional ball and roller bearings where their resistance to deformation comes from the way they are press-fit into a sturdy housing.

Endplates

Stud-style cam followers feature one integrated end plate into the inner raceway and another that is pressed onto the stud up to to a shoulder. This allows flexibility for stud hardness.

Traditional and Crowned OD

The working face of every cam follower assembly is the outer diameter and is commonly composed of traditional bearing steels, like 52100 or 100Cr6 . This working face contacts another surface rotating the cam follower and transmitting or guiding power. While a flat and cylindrical shape for the outer diameter of a cam follower is simple, a crowned design offers unique advantages, especially for applications utilizing linear motion.

With a crowned cam follower, loads are more evenly distributed during deflection and operate with minor misalignment preventing corner loading (stress concentrations) and reducing thrust loads for applications utilizing rotary or circular motion. Of course, this ability to operate misaligned comes at the cost of a reduced load capacity.

Rollers

Needle rollers are commonly used in cam followers for the ability to operate under high radial loads, but not thrust loads. Where needed cam followers can be produced with a double row roller configuration. For applications experiencing radial and axial loads, ball or tapered roller bearings may be recommended.

Lubricants

Cam followers benefit from using oil for high speed applications as opposed to grease. Oil allows for bearings to stay cooler and lasts longer than traditional bearing grease. In slower moving and track applications, bearing grease is the preferred choice over oil.

Lubrication maintenance depends on the application. Those applications operating for longer periods of time or under heavy loads require regular re-lubrication. Generally speaking, most greases have a temperature limit of around 250° F (120° C). For applications requiring higher temperature limits, consider solid lube bearings .

Stud type cam followers typically are manufactured to include grease. Maintenance is performed by accessing the axial and radial lubrication holes on the stud. The mounting pin is used for lubrication with yoke type cam followers.

Common Industries and Applications

WD designs and manufactures both catalog and customized cam followers to meet the needs of niche OEMs as well as those for larger operations like:

- Forklifts

- Material handling systems

- Gearboxes

- Construction machinery

- Compressor applications

- Automobile plants

- Industrial robotics

- Electric motors and parts production

- Machine tools

- Office automation equipment

- Food and beverage

- Forestry equipment

- Steel mills

- Textiles

- Packaging equipment

Contact Us Now

We believe in quick and efficient communication. For more information, feel free to:

- Use our Live Chat feature to chat with us right now . No robots – just us! Simply click the chat icon on the bottom right of your screen.

- Call or email our knowledgeable, non-commission sales team.

- Send us a message using our quick and easy contact form.

WD Bearing Group produces the whole range of cam followers, both standard and non-standard designs. Customized cam followers are available to fit your application as well as a risk-free application review where we provide our engineering recommendations to improve your application or reduce your operating costs.

Celebrating 21 years of bearing experience in 2021

Precision Bearings Manufactured Entirely In-House.

"WD is the bearing manufacturer I wish I found ages ago."

Manufacturing and Quality Control

We source our high-quality 99.98% VIM-VAR steel and move it directly into our production facility where grinding, turning, heat-treating, assembly, and washing occurs. Our quality assurance and control teams constantly evaluate our product until they ship to the customer.

Engineering and Local Support

WD Bearing manufacturing headquarters is a 20,000 m² facility with a dedicated 140 m² quality and inspection room. Our engineering labs in Europe and North America extend our quality control, service, and sales to the entire world. Our global footprint affords our customers local support from our sales and service teams anywhere on Earth.

Experience and Partnerships

WD Bearing Group has crafted a team with hundreds of years of engineering experience collectively. Our engineers have developed applications used by NASA on the Mars rover, the construction of the World Trade Center, and numerous bearing-specific applications with popular OEMs around the world.

We're ready to help.

Let's start something great together.

Upgrade your application. Save costs and improve performance.