Material Handling Equipment

Move, Protect, and Control Your Materials

Industries We Serve

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Material Handling Equipment: Components and Bearings

Material handling equipment is present in every manufacturing facility in the world. Your business produces these tools every day to help move products from point A to point B and beyond. Without them, your customers would not be able to move your products nearly as efficiently, which is why every aspect of this equipment needs careful selection.

WD Bearing’s selection of components and bearings offers part solutions for most material handling equipment on the market so you can develop robust equipment for your customers.

What Is Material Handling Equipment?

Simply put, material handling equipment encompasses any tool you use to move, lift or store products within a facility and during the shipping process. This might include forklifts, shelving, conveyor belts, pallets, elevators, silos, retrieval systems and racks. Material handling equipment is usually broken down into four categories:

- Transportation equipment: Tools that move your customer’s products

- Positioning equipment: Tools that help retrieve and distribute their products

- Storage equipment: Tools that keep products in place for storage

- Bulk material equipment: Tools that make large equipment and loads easier to group and distribute

The Physical Influence of Bearings in Material Handling Equipment

As such a small component of much larger machines, your equipment’s bearings rarely receive much consideration. Still, they play a vital role in many operations, as they’re responsible for contributing to:

- Speed, torque and horsepower generation

- Continuous or intermittent operations

- Radial load support

- Space allocation

Overall Bearing Life

Every part of your material handling equipment design needs to be constructed with maximum durability and longevity in mind. At WD Bearings, we do this by using 99.98% VIM-VAR steel, resulting in minimal bearing strain and optimizing performance.

Product Consistency

Every part of our manufacturing process is regulated and monitored to ensure we produce the same bearings in every batch. A consistent product contributes to consistent results, allowing for increased efficiency in the workplace.

Fracture Resistance

Every force your customers exhibit on your material handling equipment is transferred through the parts of said tools. Our bearings are designed to take this force through the addition of large rivets, strong retainers, alternative materials, and more.

Common Bearing Types:

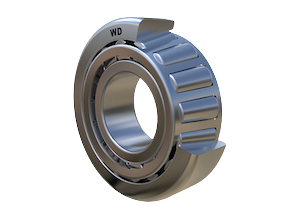

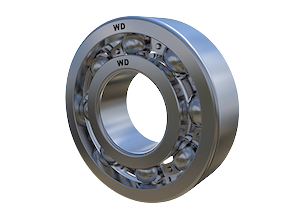

Our engineers manufacture custom bearings for all your needs. Our most popular products include:

- Cam followers: Cam followers or track followers are crucial in the oscillation movement, precision rotation, or linear movement.

- Cylindrical roller bearings: In high-performance material handling equipment, cylindrical roller bearings are necessary. They’re able to manage heavy radial loads and high-speed movements due to their low friction output.

- Tapered roller bearings: These lifting equipment bearings easily manage axial loads, making them an ideal solution for gearboxes and forklifts.

- Deep groove ball bearings: This is the most common bearing type due to its reputation for low noise and friction output. Deep groove ball bearings are an excellent choice.

Get the Most out of Your Bearings

Bearings are necessary everywhere, from the automobile industry to food processing and material refineries. When you need new bearings for your lifting equipment or other material handling solutions, trust the team at WD Bearings. We’re ready to handle your largest requests, including requirements for custom product designs. Learn more about how our bearings can enhance your material handling equipment and contact us today for a quote.