Seeders and Planters

Agriculture Machinery - Serving OEM Partners Worldwide

Industries We Serve

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Seeders and Planters: Components and Bearings

Seeding machines and planting machines are the technological marvels allowing the most fundamental farming procedure to be done with ultra-precision – digging holes, planting seeds, and covering them up with soil.

Of course, simple does not mean easy. There is no room for error or breakdowns f or farmers and OEMs when time is money, especially in the agriculture industry. Getting everything right on the first try is paramount to an efficient and profitable growing season. When your customers are in this industry, an OEM’s currency is “reliability”.

Bearings need to be first on your list of decisions to inevitably improve machine performance, increase the lifetime of operation, and lead your customers to a confidence in your brand.

A Comparison: Seeding Machines and Planting Machines

Seeding machines and planting machines share many similarities. Seeder machines (sometimes called drills) and planters, regardless of type, operate in the same basic fashion. Knowing this information can help you to spot areas where your equipment can run more efficiently.

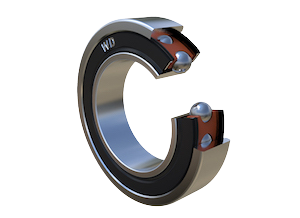

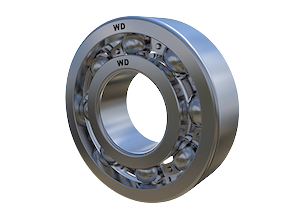

Both machines utilize double or triple-sealed bearings to prevent debris, disc openers to smooth edges and dig trenches, gauge wheels to set seed depth and rotate the seed plate, and closing discs to cover the seeds with soil.

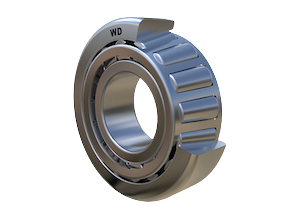

Modern machines are often equipped with tapered roller bearings , deep groove ball bearings, and advanced seals to limit debris and obstructions from entering into bearings.

What is a Seeding Machine (Seeder, Seed Drill)

The uses of seeders or seeding machines in agriculture sows seeds for crops by dropping seeds into a straight furrow within the soil at precise rates and specific depths. With seeding machines, seeds are distributed in rows; however, the distance between seeds along the row cannot be adjusted due to the nature of working with smaller seeds like cereals and grains.

Most modern seeders hold their seed in a hopper from which seeds are transported into tubes via air.

What is a Planting Machine (Planter, Seed Planter)

Seed Planter machines are kings of precision. The uses of planters in agriculture is for crops that thrive in precise conditions like corn and sunflowers, ensuring consistent plant spacing in addition to row spacing and seed depth are of great importance.

Planters work much the same as seeders except instead of air to transport the seed, it is common to see a vacuum system where seed is taken from a large hopper to individual hoppers for each row and forced into the ground in neat rows via a short, powerful blast of pressurized air.

Seeds move into a disc (or seed meter) with a set number of holes large enough for just one seed (typically larger seeds like corn). As that disc rotates seeds will drop through the holes at specific and measured increments. This allows for seed distance to be managed in a way that is precise and predictable.

The Role Bearings Play

The gauge, opening, and closing wheels along with the seed meter are the most important parts of this giant machine. Without proper operation of these integral components, down time, break downs, and loss of revenue are sure to ensue.

OEMs need high-quality steel bearings with advanced seals to outlast the discs in any seeding machine or planting machine.

High-Quality Steel: Maximize Bearing Life

When bearings are made from 99.98% VIM-VAR steel like they are at WD Bearings, the confidence that bearings will perform well-past the lifetime of an agricultural disc is next to none. Avoiding fatigue is a major advantage to capitalize on when choosing bearings. Bearings worth being in your seeding and planting machines require high-quality steel to improve upon bearing fatigue and operation performance.

Advanced Seals: Prevent Contamination

There are fewer industries dirtier than agriculture. Even if you have high-quality steel bearings, they are only as useful as the seals protecting them from mud, dirt, grime, fluids, and the intense usage they experience.

Product Consistency: Expect Reliability

Quality creates value. Period. Consistent manufacturing, ball and roller selections, and quality control management is often overlooked when choosing bearings to create reliable machines. When a product is the same with every order, expectations can be met confidently. Consistent manufacturing processes and suppliers allow for machinery OEMs to be confident in their applications operating as intended day-after-day.

The Social Influence of Bearings in Seeding and Planting Machines:

It is paramount to the successful operation of any OEM of seeding and planting machines to carefully consider the bearings they choose. When generating rotation is the method of distributing seed, what does it say when bearings are overlooked? In many ways the decisions made with bearings influence the overall performance and lifetime of seeding and planting machinery which affects customer relationships, revenue, and perception of brand.

The bearings within planters and seeders, like other components, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

We have a robust selection of roller and radial bearings such as tapered roller bearings, angular contact roller bearings, and deep groove ball bearings.

Get the Most Out of Your Bearings

As an OEM, you need reliable bearings in the machinery you create.

Seeding machines and planting machines are everywhere. And those in the agriculture industry know the difference between quality craftsmanship and poorly-made scrap. Understanding the crucial relationship between quality bearing components and agriculture machinery performance pays dividends for both you and your customers.

For more information or to order our services, contact us today.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.