Innovative

Bearing Production

Find out what’s possible with a no-obligation application review.

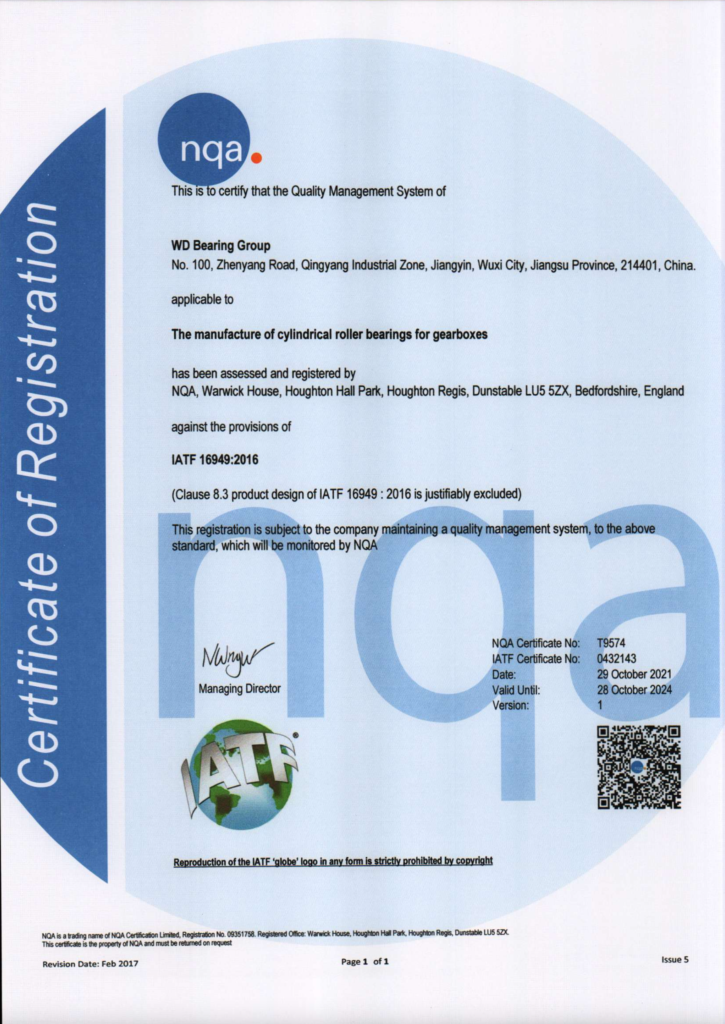

Technology-Focused | ISO and IATF Certified

WD Bearing Group is proud to manufacture products in accordance with Six Sigma principles and quality management systems including ISO 9001, ISO 14001, and IATF 16949. We continuously invest in advanced machining equipment, professional bearing software, and highly skilled employees. This focus makes WD Bearing Group the customer’s preferred partner for bearing technology, and bearing manufacturing services.

WD bearings are frequently supplied to OEMs in several industries including material handling , agriculture , construction , pump and compressor , gearbox , electric motor, and more.

We Resolve Your Challenges

Our vision for you is one that blends simplicity with expertise. Experience our seamless approach where your needs are met without complexities.

Take advantage of our award-winning engineering and sales teams to secure the optimal bearing solution for your requirements.

Discover your opportunities with our risk-free application review and have recommendations within days, not weeks.

- Flexible Manufacturing

- Product Validation

- Low MOQ or Low MOQ Available

- Personalized Solutions

- Unlimited Design Revisions

Industries We Serve:

At WD, our advanced bearing manufacturing process is engineered to empower your success across diverse applications, ensuring you have the robust capabilities necessary to excel in your industry.

Pump & Compressor

Gearbox

Material Handling

Agricultural Machinery

Construction Machinery

Providing High-Quality Bearings Manufacturing Worldwide

Our mission is to stoke the common good between business and mankind by supplying the world with quality bearings and crafting meaningful partnerships.

Helping you achieve your mission is how we accomplish ours.

Celebrating 25 Years of Bearing Experience In 2025

Precision Bearings Manufactured Entirely In-House.

"WD is the bearing manufacturer I wish I found ages ago."

Manufacturing and Quality Control

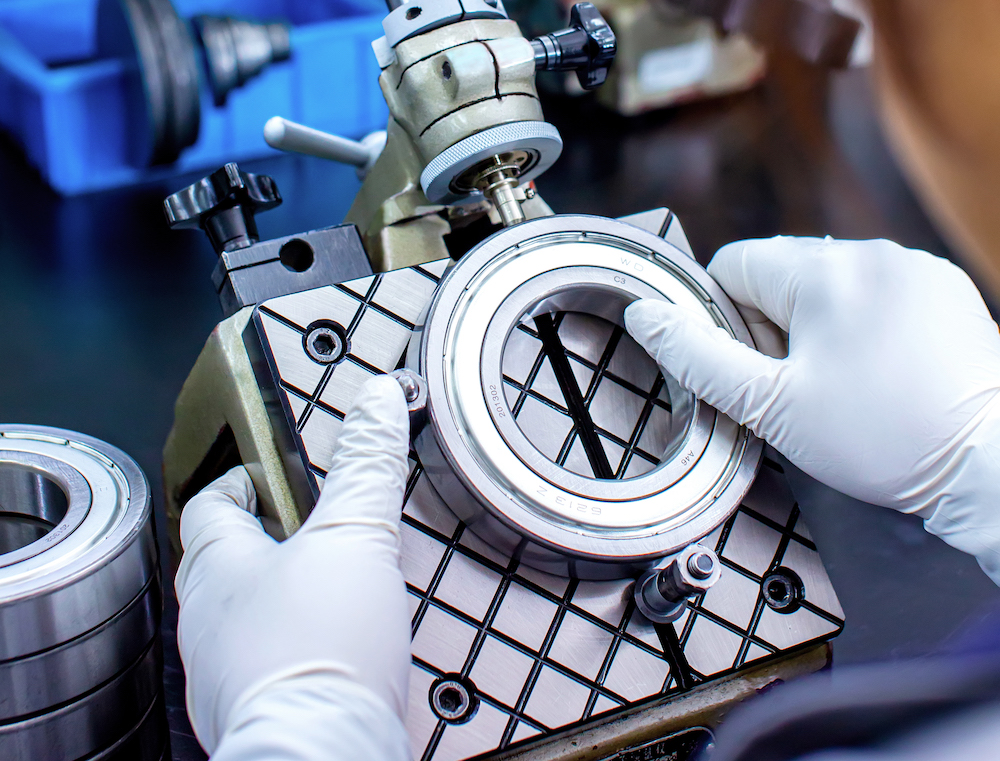

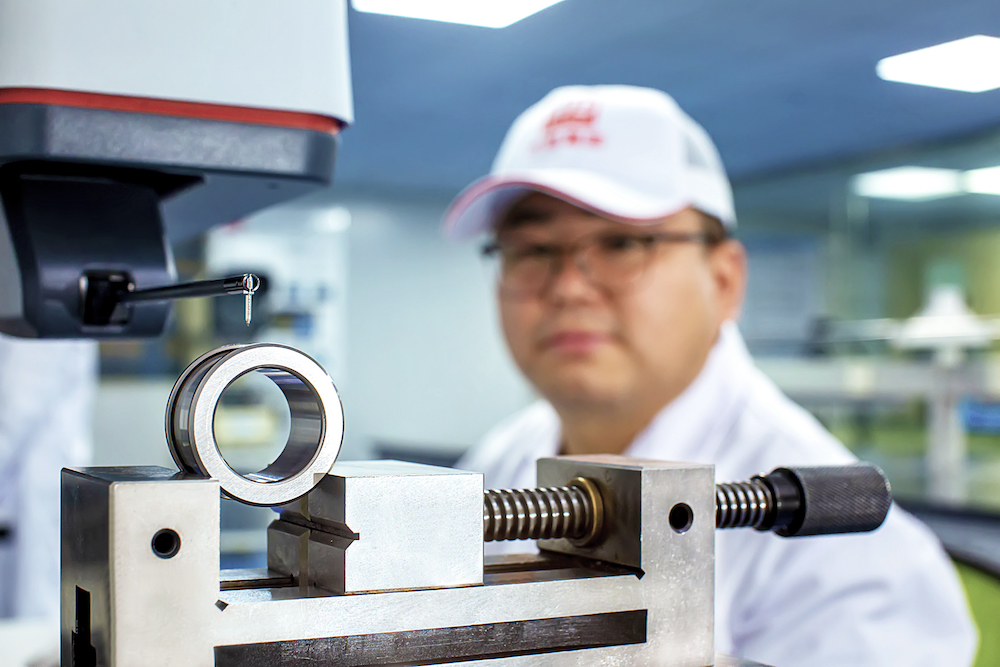

We source our high-quality 99.98% VIM steel and move it directly into our production facility where grinding, turning, heat-treating, assembly, and washing occurs. Our quality assurance and control teams constantly evaluate our product until they ship to the customer.

Engineering and Local Support

WD Bearing manufacturing headquarters is a 20,000 m² facility with a dedicated 140 m² quality and inspection room. Our engineering labs in Europe and North America extend our quality control, service, and sales to the entire world. Our global presence ensures that our customers receive local support from our dedicated sales and service teams, regardless of their location worldwide.

Experience and Partnerships

WD Bearing Group has crafted a team with hundreds of years of engineering experience collectively. Our engineers have developed applications used by NASA on the Mars rover, the construction of the World Trade Center, and numerous bearing-specific applications with popular OEMs around the world.

Let's start something great together.

Upgrade your application. Save costs and improve performance.