Conveyor Equipment Bearings

Move, Protect, and Control Your Materials

Industries We Serve

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Conveyor Equipment: Components and Bearings

In the industrial manufacturing setting, conveyor equipment assists in assembling, inspecting, packaging, and distributing your product. Because it’s so versatile and contributes to so many tasks, it needs to work perfectly, all day, every day. That means every component that makes it run should be durable and efficient — even the smallest parts, like conveyor roller bearings.

At WD, bearings are our specialty. We specialize in optimizing heavy machinery through custom components and bearings designed to help you work better and keep your facility running as it should.

What Is Conveyor Equipment?

Conveyor equipment comprises any tools, equipment, or parts involved in a conveyor system. Conveyor systems are responsible for carrying your product — or parts of your products — from one point to another. They may transport anything but are particularly useful in moving things that are too heavy for human hands to manage. Other benefits of conveyors include:

- Reducing instances of human error

- Reducing labor costs

- Maximizing workplace safety

Because they often deal with heavy loads, your conveyor equipment should use the best of the best in parts and replacements.

The Physical Influence of Bearings in Conveyor Equipment:

Conveyors are capable of powerful work, but to achieve optimal function, every part must be chosen carefully to work in alignment. Bearings affect a range of factors in any conveyor, including:

- Horsepower, torque, and speed requirements

- Radial and axial load amounts

- Continuous and intermittent operational needs

When considering your options for bearing producers, keep these points in mind.

Overall Bearing Life

To get the maximum life span from your equipment, you need parts constructed from the best materials. Our bearings are sourced from 99.98% VIM-VAR steel to ensure longevity.

Product Consistency

Consistent manufacturing delivers consistent results. We pay close attention to every step of our conveyor roller bearing construction so that every part yields the strength and effectiveness we’re known for.

Fracture Resistance

When heavy products and equipment roll down your conveyor system, your bearings must be strong enough to handle them without excess strain. Our bearings have reinforcements like robust rivets and retainers to maintain adequate fracture resistance.

Common Bearings:

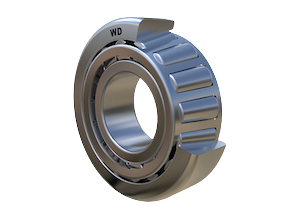

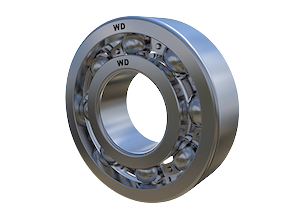

While WD Bearings delivers superior performance in all bearing types, it’s essential you find the right conveyor bearing types for your equipment. Most conveyor systems use these bearings in their construction:

- Deep groove ball bearings: Deep groove ball bearings are the most common type of bearing, as they’re optimized to reduce noise pollution. Their design produces minimal friction, which can help your conveyor belts move items smoothly and efficiently.

- Tapered roller bearings: When strength and versatility are paramount, make sure tapered roller bearings are part of your construction. They’re useful in managing both radial and axial forces, which can be significant in conveyor system operations.

Get the Most out of Your Bearings

Every industrial manufacturing facility requires equipment capable of handling its most complex and demanding applications. At WD Bearings, our custom components are built to last, even when facing your largest jobs yet. Learn more about how our ball bearings for conveyor rollers can optimize efficiency and power your projects by reaching out today . We’ll help you determine the right bearings for you and deliver a quote on our parts.