Agriculture Machinery

Serving OEM Partners Worldwide

Industries We Serve

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Tillage Machinery: Components and Bearings

Tillage machinery is as integral to the agriculture industry as seeding, planting, and harvesting. It may even be more important given improper or insufficient tillage causes challenges for the upcoming growing season if the harvest even begins growing.

These specialized implements and equipment are designed to manipulate soil in a variety of ways and for many purposes. Tilling implements mechanically agitate soil to help to open up soil compaction and rutting. prepare seed beds, introduce amendments to the soil, manage crop residue, and control weeds.

Common Tillage Components

Modern tillage machinery operates by moving a collection of soil-disrupting devices through the ground via motorized power. Rotating tines or blades are either self-propelled or drawn behind a tractor with the help of a power take off unit.

Ganged Disc Tillage Machinery

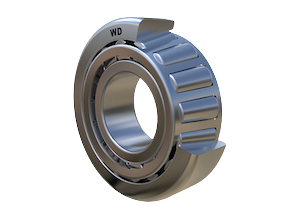

A typical North American option, ganged discs are closely spaced discs supported by trunnion bearings on each end of a shaft. There are typically 2-3 bearings per gang (group of discs) which have round or square bores axially clamped by mating components.

Independent Disc Tillage Machinery

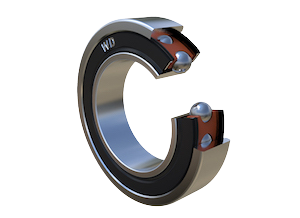

What started as a common European design is now becoming more popular in North America. Tillage with independent discs are not ganged together and are instead mounted on hub units with double row or tapered roller bearings. The design of these discs allow for dynamic misalignment to be absorbed by the arm instead of the bearing and it is common to see disc harrows associated with this type of tillage.

Rolling Basket

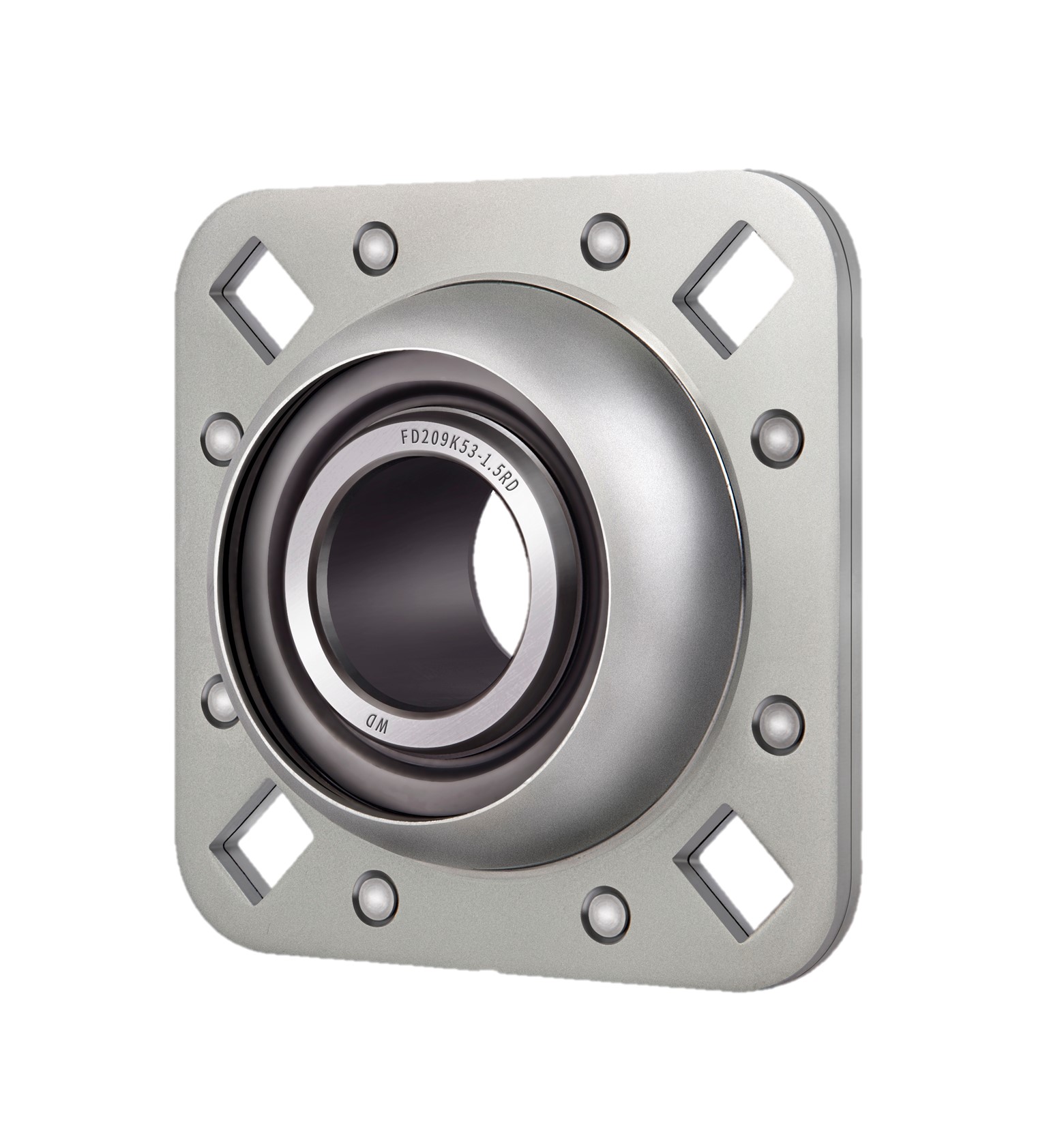

Strictly used to settle and flatten soil after tillage, this is an optional attachment pulled behind other tillage implements and have bearings which are permanently riveted into heavy stamped flangettes. These flangettes protect seals from crop wrap and other debris.

Rolling baskets are supported by flange bearings on each end, typically round or square bore flange disc units. With square units, a locking mechanism is not required and shaft rotation is eliminated. Round units, however, require a locking mechanism to attach to the shaft to avoid slippage.

The Role Bearings Play

Bearings are critical components for tillage machinery, not commodities .

Bearings are the most-integral unit between soil contact and machinery. A bearing failure leads to catastrophic failure for tillage machinery. Bearings that seize or fatigue too quickly leads to down time, break downs, and loss of revenue.

High-Quality Steel: Maximize Bearing Life

When bearings are made from 99.98% VIM-VAR steel like they are at WD Bearings, the confidence that bearings will perform well-past the lifetime of an agricultural disc is next to none. Avoiding fatigue is a major advantage to capitalize on when choosing bearings. Bearings worth being in your tillage machinery require high-quality steel to improve upon bearing fatigue and improves operation performance.

Advanced Seals: Prevent Contamination

There are fewer industries dirtier than agriculture. Even if you have high-quality steel bearings, they are only as useful as the seals that protect them from mud, dirt, grime, fluids, and the intense usage they experience.

Product Consistency: Expect Reliability

Quality creates value. Period. Consistent manufacturing, ball and roller selection, and quality control management is often overlooked when choosing bearings to create reliable machines. When a product is the same with every order, expectations can be met confidently. Consistent manufacturing processes and suppliers allow for machinery OEMs to be confident in their applications operating as intended day-after-day.

Tillage Bearing Failures

Bearings are essential to well-working farming equipment and ensure machinery, shafts, and components are rotating properly. Harsh weather conditions and inadequate lubrication are some of the challenges faced when maintaining bearings and equipment.

Hard particles and foreign materials, such as dirt and debris, can easily contaminate bearings causing them to deteriorate. When worn, bearing create misalignments and experience reduced life. Bearings within tillage machinery have predictable patterns for failure given the application. Corrosion from moisture, wear/looseness due to contact with soil, insufficient lubrication, dynamic misalignment from loose housings, and seal lip damage are all issues that quickly become detrimental to bearing performance.

Protection against contamination saves cost with grease and labor, offers more time in the field, and has reduces environmental impact. Bearings which are free from contaminants and debris offer a longer life and improved dynamic alignment capability.

The Social Influence of Bearings in Seeding and Planting Machines:

It is paramount to the successful operation of any OEM of tillage machinery to carefully consider the bearings they choose. When generating rotation is the method of preparing soil, what does it say when bearings are overlooked? In many ways, the decisions made with bearings influence the overall performance and lifetime of tillage machinery which affects customer relationships, revenue, and perception of brand.

The bearings within tillage implements, like other components, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

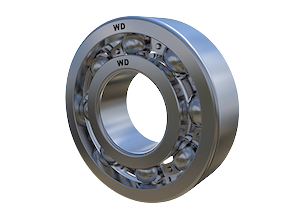

We have a robust selection of roller and radial bearings such as tapered roller bearings, angular contact roller bearings, and deep groove ball bearings.

Get the Most Out of Your Bearings

As an OEM, you need reliable bearings in the machinery you create.

Tillage machinery is everywhere. And those in the agriculture industry know the difference between quality craftsmanship and poorly-made scrap. Understanding the crucial relationship between quality bearing components and agriculture machinery performance pays dividends for both you and your customers.

For more information or to order our services, contact us today.

Enhance Your Equipment Performance

Factors like quality of seals and bearing material when used to manufacture bearings will affect performance and safety depending on load size, speed, and frequency of use of your tillage equipment.

If you’re concerned about the quality of your current tillage bearings, consider getting in touch with an expert in the industry . Now is a great time to make necessary equipment upgrades to ensure the success of your business.

For more information or to request a quote, contact us today.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.