Agriculture Machinery

Serving OEM Partners Worldwide

Industries We Serve

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Combine Harvesters: Components and Bearings

Combine harvesters get their name from the way they reap, thresh, gather, and winnow all in one process. These versatile machines are crucial tools for farmers to increase efficiency, save time, and reduce labor costs.

This versatility makes combine harvesters some of the most complex machinery in the agriculture industry being made with over 20 different major components.

What Is a Combine Harvester?

The process of harvesting with a combine, while complex, is a simple pathway designed to pull a crop from the ground and save the valuable parts of the plant while discarding the rest.

The header is responsible to pull in the crop into the cutter bar which is then cut down to be gathered by the revolving reel. This reel feeds the crops into the threshing area to separate the grains from their stalks where grains move to a location to be delivered into a truck while stalks are discarded back onto the ground outside of the combine harvester.

Components of Combine Harvesters

The header is responsible to pull in the crop into the cutter bar which is then cut down to be gathered by the revolving reel. This reel feeds the crops into the threshing area to separate the grains from their stalks where grains move to a location to be delivered into a truck while stalks are discarded back onto the ground outside of the combine harvester.

Header

The role of the header (or grain platform) is simply to cut the plant close to the ground and move the plant into the combine harvester. The header cuts the crops with a reciprocating knife bar and serrated revolving reels.

Of course, there are many kinds of headers available; the proper choice is dependent on the crop being harvested.

Feederhouse

The feeder throat, commonly called the feederhouse, forces crops to move toward the middle of the combine harvester with the help of spinning augers and a conveyor.

Cylinder (Threshing Drum)

Crops at this point are still completely connected. A threshing drum beats the cut crops to break and shake the grains away from their stalks. The grains fall through sieves into a collecting tank below. The unwanted material (chaff and stalks) passes along conveyors called straw walkers toward the back of the machine. This is done by using grooved steel bars or rasp bars along with meshed grills for smaller debris to escape. Larger debris continues to move along another conveyor to be discarded.

Grain Tank

The valuable parts of the plant, such as grain, that were separated from their chaff in the threshing drum move into a holding place called the grain tank. The grain is carried up from the tank by an unloader and shoots out of a side pipe into the trailer.

The Role Bearings Play in Combine Harvesters

There isn’t an agricultural machine more dependent on predictable motion than the combine harvester. Period.

A purpose of a bearing is to provide efficient motion with as little friction as possible. The debris produced from combine harvesters alone can wreak havoc on bearings without proper seals let alone the massive radial loads experienced by the bearings from routine operation.

Maximized Operating Time with High Quality Steel

Combine harvesters have one of the most intense jobs in agriculture. We know that down time from bearing failures risks revenue whether you’re an OEM or have boots on the ground.

We here at WD source 99.98% VIM-VAR steel for our bearings. Why? Because material quality is one of the most important components to maximizing bearing lifetimes. Bearings worth being in your combine harvesters should have forged inner and outer rings to improve upon bearing fatigue, too. in addition rolled inner and outer raceways.

Predictable and Reliable Operation with Bearing Consistency

Quality creates value. Period. Consistent manufacturing, ball and roller selections, and quality control management is often overlooked when choosing bearings to create reliable machines. When a product is the same with every order, expectations can be met confidently. Consistent manufacturing processes and suppliers allow for machinery OEMs to be confident in their applications operating as intended day-after-day.

Precise Operation with Bearing Misalignment Capacity

As stated earlier, combine harvesters have intense demands placed on them. They need to have a high tolerance to radial loads and solid impact resistance. We optimize our bearings to maximize their strength through ideas like increasing their shoulder heights (among others things) to ensure our bearings can take a beating and continue their work.

The Social Influence of Bearings Choice:

It is paramount to the successful operation of any OEM of combine harvesting equipment to carefully consider the bearings they choose. When generating motion is the method of efficiently harvesting the fruits of a season of work, what does it say when bearings are overlooked? In many ways the decisions made with bearings influence the overall performance and lifetime of combine harvesters affecting customer relationships, revenue, and perception of brand.

The bearings within combine harvesters, like other components,, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review. We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

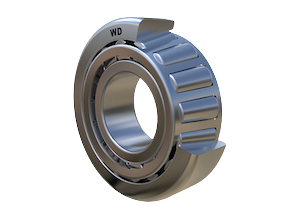

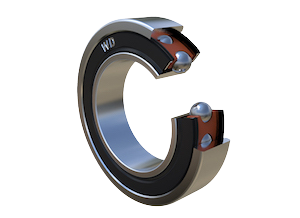

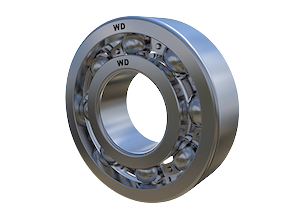

We have a robust selection of roller and radial bearings such as tapered roller bearings, angular contact roller bearings , and deep groove ball bearings.

Get the Most Out of Your Bearings

As an OEM, you need reliable bearings in the machinery you create.

Combine harvesters are crucial to the success of the agriculture industry. And those in the agriculture industry know the difference between quality craftsmanship and poorly-made scrap. Understanding the crucial relationship between quality bearing components and combine harvester performance pays dividends for both you and your customers.

For more information or to order our services, contact us today.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

WD listened to our needs and accurately provided high-quality bearing products that fully met our requirements. These ensure that our customers have a high level of trust in the quality of our products.

European Machinery OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.