Pump & Compressor Bearings

High Precision, Low Noise, Long Life

Industries We Serve

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Pumps and Compressors: Components and Bearings

Pumps perform many essential functions, heating entire homes and keeping the air cool in refrigerators. Compressors pump air into tires and fill vehicles with gasoline. From air conditioners to jackhammers, many types of machines use these components to transfer liquids and gases from place to place.

When you want to take your application to the next level, you can count on solutions from WD Bearings. Our company tailors high-quality designs with robust materials and manufacturing processes.

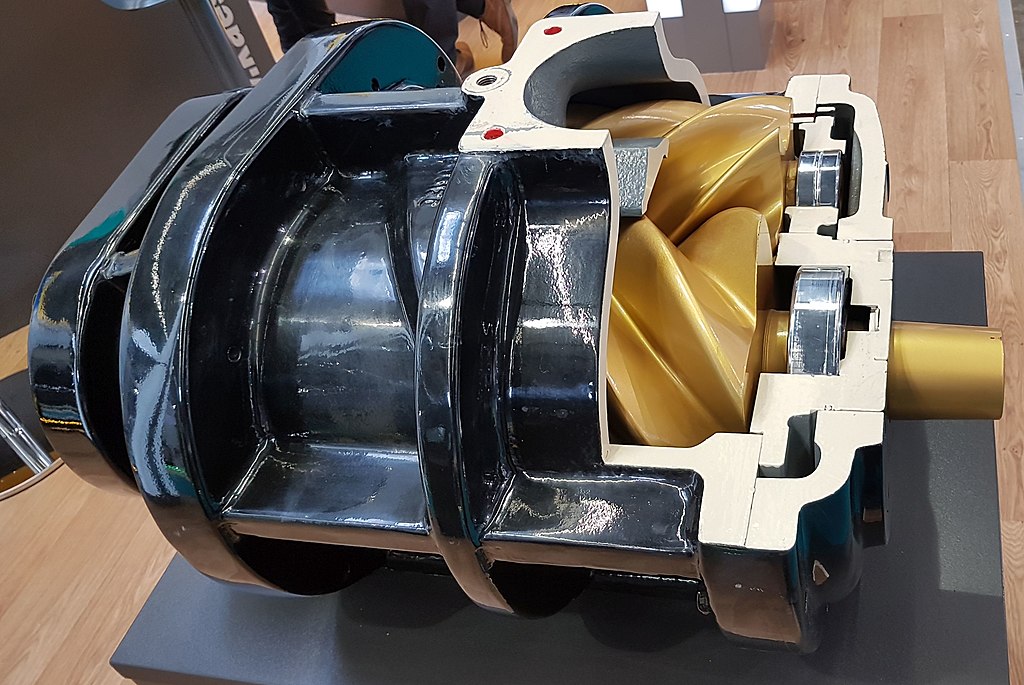

What Are Pumps and Compressors?

Generally, pumps are best suited for water, oil, and other liquids. They can operate with gases or fluid substances as well. The pump’s engine converts mechanical energy into kinetic energy. As the pressure increases, the medium flows from a suction pipe and discharges into an outlet pipe. The medium’s volume stays consistent throughout this process.

Dynamic pumps move liquid using force in a space connected to the suction and pressure pipelines. Positive displacement pumps move liquid using periodic changes of the volume in a space occupied by the liquid, which occasionally alternates between the suction and pressure pipelines. Pumps have applications in many industries, including refrigeration, air conditioning, mining, and irrigation.

Compressors accommodate air, gas, and vapor. The mechanical energy is stored in the gas as potential energy. As the pressure increases throughout the operation, the medium’s volume decreases. Some compressors feature attached storage, allowing you to reserve compressed gases and deliver them as needed. Compressors have broad applications, including use in refrigeration technology, processing, breweries, refineries, and technical gas plants.

The Physical Influence of Bearings in Pumps and Compressors

Turn to WD Bearings for pump and compressor bearings you can rely on to support loads. The pump bearings allow for heavy loads and high speed, while the compressor bearings accommodate radial or axial positioning.

Overall Bearing Life

Our company uses 99.98% VIM-VAR steel for most of our bearings. The robust material reduces wear and tear for a longer life expectancy.

Product Consistency

We follow consistent manufacturing and management processes for unwavering quality. You can feel confident knowing the bearings will function as intended in your day-to-day operations.

Fracture Resistance

Our compressor and pump bearings are designed with durable components. The pieces accommodate pressure through the compression of gases or the transfer of fluids and liquids.

Common Bearings in Pumps and Compressors

Some signs of good bearings include smooth and efficient operations. Experts at WD Bearings can provide guidance when choosing from the following options:

- Tapered roller bearing: A tapered roller bearing transfers axial and radial loads evenly.

- Deep grove ball bearing: The deep grove ball bearing carries radial and axial loads quickly.

- Angular contact bearing: An angular contact bearing handles radial and axial loads.

- Cylindrical roller bearing: The cylindrical roller bearing favors radial loads and light axial loading.

- Four-point contact ball bearing: A four-point contact ball bearing supports radial and axial loads in both directions.

Get the Most out of Your Bearings

Ready to optimize your operations? To get started, request a quote today!