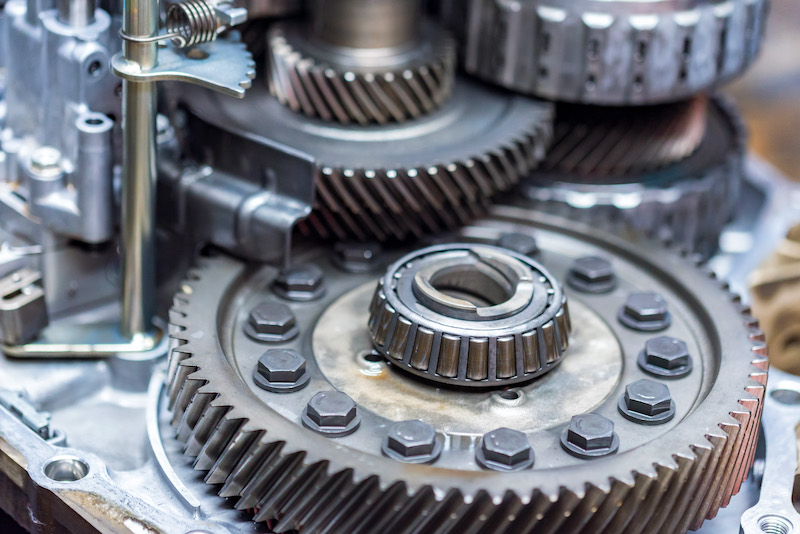

Cylindrical Roller Bearings

Cylindrical roller bearings manufactured with premium VIM steel, in-house heat treatment, optimized rib and raceway design, and special clearance control. These specialized catalog and customizable cylindrical roller bearings excel under aggressive radial loads and environmental conditions.

The WD Edge:

- Catalog and customizable bearing designs, cages, precisions, and greases

- Forged VIM steel standard, 99.98% VIM-VAR steel available for extended bearing life

- Flexible materials: 100Cr6, PA12, GCr15, 20CrMo, 30CrMo, and AISI 52100 (Ti < 30 PPM)

- Available with steel, brass, nylon, polyamide, PEEK, and PPS cages

- In-house heat treatment: Through-hardened, induction-hardened, or salt bath quenched

- Optimized rib and raceway design for enhanced axial load capacity and lubrication flow-through

- Minimized raceway undercut and logarithmic roller profile for maximum radial load capacity

- Managed with special clearance control for improved bearing rotation under high speed and eccentric loads

- Available with CorroFree720, nickel-plated, and black oxide surface treatments

- Manufacturing N, NJ, NU, NUP in series 2XX, 3XX, 22XX, 23XX and RN, RNN, and SL

- Standard production range: ID 20mm – OD 200mm

- Variable precision, vibration, and sound ratings: P0, P6, P5 | V1, V2, V3 | Z1, Z2, Z3

- Low MOQ requirements for OEMs worldwide

Manufactured In-House and Fully Customizable

Quick Links

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Cylindrical Roller Bearings: Components and Uses

Cylindrical roller bearings come in a myriad of designs, dimension series, and sizes. The most common cylindrical roller bearings have a single row of rollers with a single cage. Single and double row full complement cylindrical roller bearings without cages (with or without snap ring grooves) aid the WD standard assortment for general applications. Additionally, WD commonly manufactures special multi-row cylindrical roller bearings for the steel industry and custom cylindrical roller bearings for precision machine tools.

Components

Rollers

The rollers inside WD cylindrical roller bearings are critical components because of their role in load distribution. Although appearing “flat” these rollers utilize a profile which is more logarithmic in shape. Through a line contact between the rollers and the raceway, radial load capacity and impact load capacity for cylindrical roller bearings is as robust as it comes. For abnormal conditions, the WD engineering team provides local support and recommendations for alternative designs.

The surface finish of the cylindrical rollers helps to optimize fluid film thickness. This improves the rolling motion of the rollers and offers greater operational stability.

Rings

The inner and/or outer rings of cylindrical roller bearings guide the rollers with ribs. Ring assemblies are separable for ease of installation and press-fit individually onto the shaft and into housing.

The “ribless ring” of a cylindrical roller bearings move axially and are used as a free-end, or float bearing. Cylindrical roller bearings also offer higher stiffness, lower friction, and longer service life compared to other bearings thanks to the way they accommodate axial displacement.

Snap rings and grooves are al

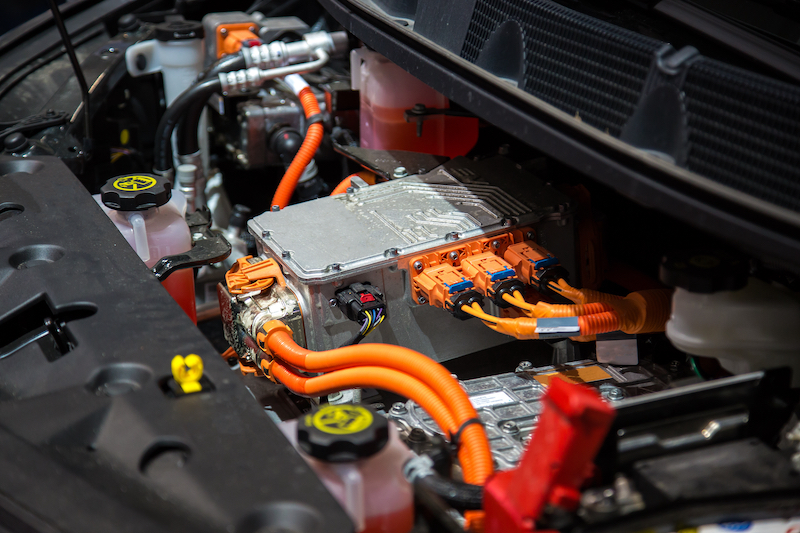

Electric Motors

Automotive Lifts

Irrigation Pumps

Cages

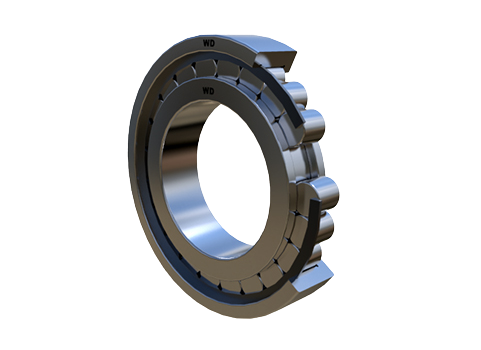

Cylindrical roller bearings utilize a cage or are manufactured as a full complement bearing to accommodate higher loads at the expense of speed. Steel, brass, and polyamide cages are common, with PEEK and PPS being less common.

Most applications, and even high-heat applications, benefit most from a steel cage. Additional chemical resistance and speed benefits are gleaned from a polyamide cage if operating temperatures do not rise about 70 degrees celsius, or about 160 degrees fahrenheit.

Types

Cylindrical roller bearings are manufactured into single, double, or multi-row configurations. The different types of bearings are designated NU, NJ, NP, NUP, N, NF for single row cylindrical bearings and NNU, NN for double row cylindrical bearings.

The range of WD cylindrical roller bearings is made up of many types and often denote differences in the inner ring or outer ring design:

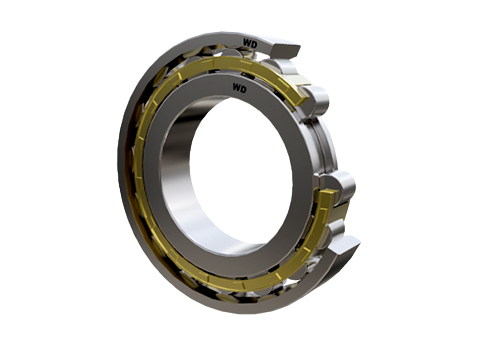

- WD single row cylindrical roller bearings – commonly NU, NJ, NUP and N designs.

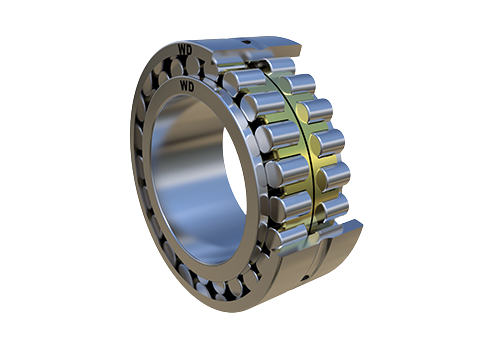

- WD double row cylindrical roller bearings – NNU and NN designs.

- WD single row full complement cylindrical roller bearings – mainly NCF and NJG designs.

- WD double row full complement cylindrical roller bearings – NNF design.

The most popular configuration is the single row cylindrical roller bearing. This is due to simple assembly, mounting, and un-mounting procedures thanks to their separability. Where the single-row configuration is popular, the double and multi-row configurations offer a greater radial load capacity and higher radial rigidity.

Cylindrical Roller Bearings are classified into the following types based on location, quantity, and type of ribs on the inner and/or outer rings.

NU, N, and NN are often free-end (“free” or “float”) bearings and are installed on the shaft away from the drive end. NJ and NF offer axial resistance in one direction while the NUP offers axial resistance in both directions, can be used as fixed-end bearings, and are installed near the drive.

Flexibility

Cylindrical roller bearings are as flexible as bearings come. Their components are interchangeable with other manufacturer’s bearings with the same dimensional size and number.

The mounting arrangements can be configured in a variety of ways and match the load capacity for a given its width, inner diameter, and outer diameter.

Cylindrical roller bearings can have rings that move freely in the axial direction (for bearings without ring ribs) for applications that experience thermal expansion of the shaft.

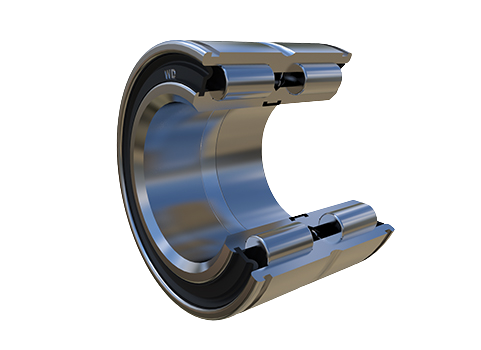

They are even available with seals or manufactured with a split design. Seals will protect your bearings from contaminants like water, dust, and mud and provide a smooth operation with an improved lubricant retention. Cylindrical roller bearings designed with a split offer a simpler maintenance and replacement process for applications with difficult access.

Contact Us now

We believe in quick and efficient communication. For more information, feel free to:

- Use our Live Chat feature to chat with us right now . No robots – just us! Simply click the chat icon on the bottom right of your screen.

- Call or email our knowledgeable, non-commision sales team.

- Send us a message using our quick and easy contact form.

WD Bearing Group produces the whole range of cylindrical roller bearings, both standard and non-standard designs. Customized cylindrical roller bearings are available to fit your application as well as a risk-free application review where we provide our engineering recommendations to improve your application or reduce your operating costs.

Celebrating 25 Years Of Bearing Experience In 2025

Precision Bearings Manufactured Entirely In-House.

"WD is the bearing manufacturer I wish I found ages ago."

Manufacturing and Quality Control

We source our high-quality 99.98% VIM-VAR steel and move it directly into our production facility where grinding, turning, heat-treating, assembly, and washing occurs. Our quality assurance and control teams constantly evaluate our product until they ship to the customer.

Engineering and Local Support

WD Bearing manufacturing headquarters is a 20,000 m² facility with a dedicated 140 m² quality and inspection room. Our engineering labs in Europe and North America extend our quality control, service, and sales to the entire world. Our global presence ensures that our customers receive local support from our dedicated sales and service teams, regardless of their location worldwide.

Experience and Partnerships

WD Bearing Group has crafted a team with hundreds of years of engineering experience collectively. Our engineers have developed applications used by NASA on the Mars rover, the construction of the World Trade Center, and numerous bearing-specific applications with popular OEMs around the world.

We're ready to help.

Let's start something great together.

Upgrade your application. Save costs and improve performance.