Forklift Bearings Quick Guide

Serving OEM Partners Worldwide

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

The Forklift Bearings Quick Guide

The Essentials

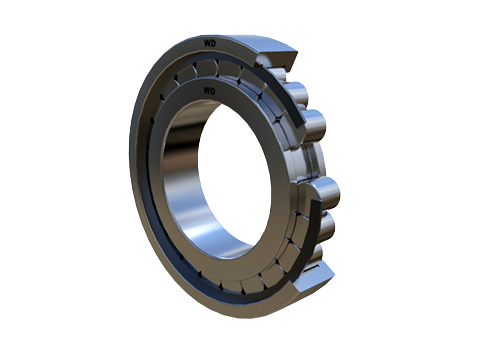

Whether you call them forklift mast guide rollers , forklift roller bearings , or mast guide bearings , these bearings are designed for heavy load carrying capacities and high intermittent shock loads, such as those in forklift applications.

The internal design of mast guide bearings and other varieties of track roller bearings maximizes load capacities to protect bearing components and applications from high radial and thrust loads. Tight seals and high grease-fills are used to ensure minimal wear and tear and the highest possible lifespan for the bearing components.

Application

Mast guide bearings are seen in cam drives, slide-ways, and conveying equipment (among other applications), and are most commonly used to guide the telescopic mast section in forklifts. In addition to mast guide bearings, forklifts often utilize carriage bearings, side thrust rollers, and chain roller bearings.

Common Mast Bearing Types:

- Mast guide bearings : As forklift masts bearings ascend and descend into position, a mast guide bearing facilitates smooth extension of each mast stage.

- Carriage bearings : These bearings are along the horizontal rail of the carriage. They allow for side-to-side positioning of the fork attachment.

- Chain roller bearings : These bearings guide chains through a profiled channel or groove as the forklift masts ascend and descend during operation.

- Side thrust rollers : A vertical roller guide that prevents bending or twisting during telescopic extension and transfers lateral loads to the mast.

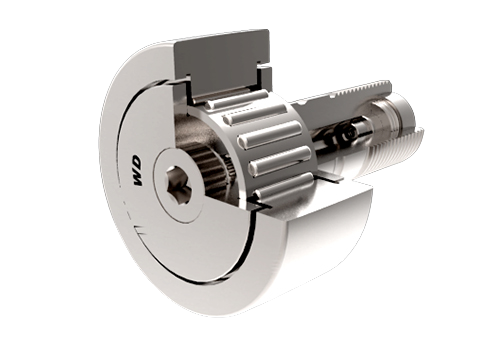

- Combined roller bearings : A bearing assembly consisting of a mast guide bearing with an integral side thrust roller. These control both the vertical and lateral movement of the mast.

Seals and Lubrication

Most mast guide bearings are lubricated and sealed to prevent contamination from getting into the rolling elements and raceways. Less frequently, mast guide bearings are shielded or open instead of sealed. Mast guide bearings are maintenance-free under normal operating conditions. However, re-lubrication is recommended for aggressive applications in tough working conditions.

Controlling contamination and lubrication is one of the simplest ways to maximize the performance of any bearing application. Discover how to make your machinery hum with the Seals and Lubrication Mini-series.

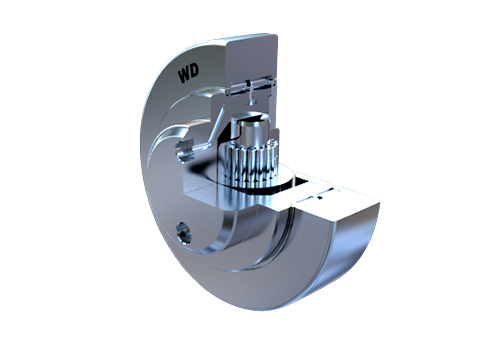

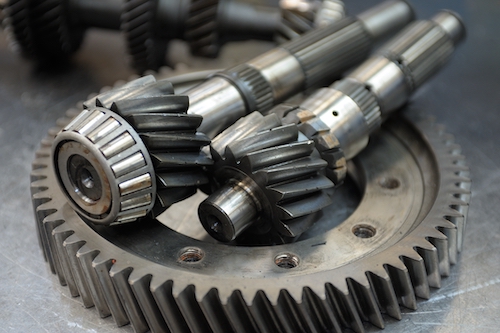

Anatomy of Mast Bearings

Outer Rings of Forklift Mast Rollers

The outer rings of mast guide bearings act as rollers and guides for the carriage in the mast profiles or rails. They are designed to fit the contour of the mast and help prevent misalignment while lifting and lowering the mast. Simply put, the outer ring is used as a wheel directly against a steel mast rail.

Due to the resulting high loads, the outer ring is heavier and thicker than a typical bearing. There are a variety of styles for outer rings which include flat, tapered, those with corner radii, chamfer, flanges, and other designs.

Configuration

In addition to the variety of outer rings profiles, mast guide bearings are available in a single row and double row configurations. Depending on the application, these mast bearings are manufactured with or without an inner ring.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

WD listened to our needs and accurately provided high-quality bearing products that fully met our requirements. These ensure that our customers have a high level of trust in the quality of our products.

European Machinery OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.