All Our Industries

.

Combine Harvester

Combine harvester is a machine that harvests grain crops. It combines three separate operations including comprising harvesting, reaping, threshing and winnowing. The combine harvester usually has a long period of inactivity, and then an intense period of work and exposure to dust, mud and heavy vibration which increase the risk of bearing failure.

WD Solution:

WD provides high quality bearings for combine harvester to withstand the intense work schedules. Lubrication-free bearings and special sealing solutions enable more uptime in the severe environment. And when repairs are required, the integrated and easy-to-fit WD bearings can speed the installation time. WD solution can help you to improve the productivity.

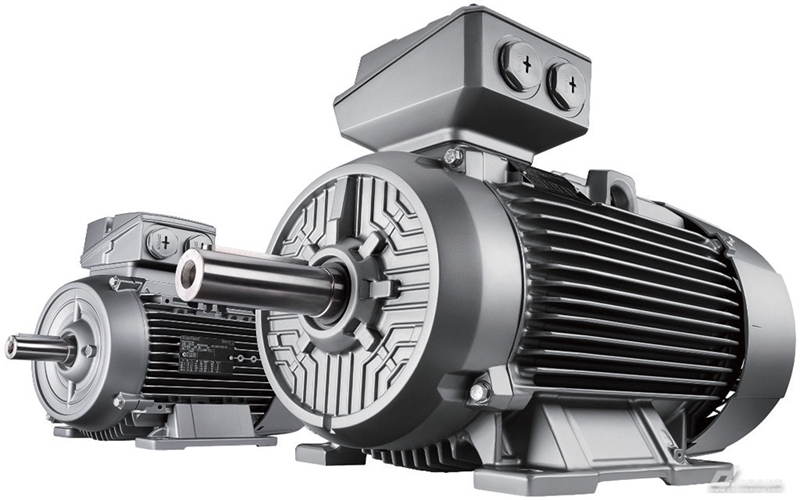

Electric Motor

Typical product: WD EMQ bearings, e.g. 62 series P5 ZV4

Electric motors are used as the source of motive power in all kinds of industries. Nowadays, customers have increasing needs for electric motors with low energy consumption. There is also a demand for longer operational life, higher reliability with cost saving in this highly competitive industry.

WD Solution:

Through the close cooperation with manufacturers, WD is experienced in bearings for the electric motor industry. In addition to a wide range of bearings, our customers also have access to WD‘s excellent engineering services. Our application engineers optimize customer’s bearing solutions by choosing the bearing dimension, precision, vibration & noise, clearance, lubrication and sealing that are best suited to customer’s unique application. These services help customer to reduce the total cost and create more value.

Now, in order to meet the ever increasing demands for flexible quantity and shorter delivery time, WD has build up the EMQ bearing inventory for sale. Please contact sales@wd-bearing.com for more information.

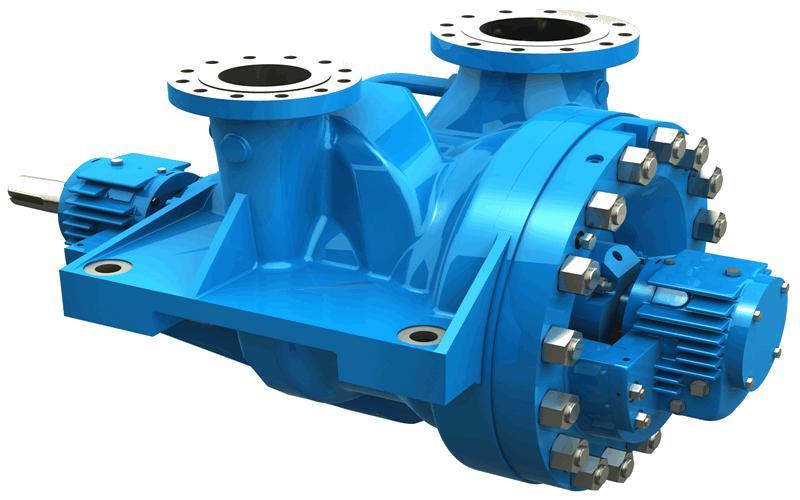

Industrial Pump

Industrial pumps can be found everywhere in our modern society, from the municipal water supply system to the automobile gasoline tank. They are required to be reliable and efficient. Nowadays, the challenge for pump manufacturers is to increase the reliability and reduce the total cost at the same time.

WD

solution:

WD

has

worked

closely

with

pump

manufacturers.

We

understand

that

the

bearings

for

pumps

must

be

extremely

reliable

and

efficient.

Therefore,

we

put

great

emphasis

on

the

bearing

precision,

e.g.

the

roller

precision,

super

fining

of

the

raceway

and

the

quality

of

each

component.

The

high

precision

of

the

bearing

increases

the

operational

lifetime

and

reduce

the

energy

consumption

at

the

same

time.

By

utilizing

WD

solutions

for

industrial

pumps,

the

total

product

cost

can

be

reduced

and

more

value

can

be

created

for

customers.

Common Bearing Type:

Steel Mill

Generally speaking, the working environment in metal industry is extraordinary. Production equipment is constantly exposed to extreme temperatures, dust, contaminants and humidity which can cause costly, unexpected stops. Recurring high speeds, shock loads and big torque will always be added. For the steel manufacturers, who are facing global competition and environmental supervision, they are seeking ways to enhance efficiency and reduce costs.

WD Solution:

WD offers great competitive solutions to global steel producers. Our application experts are experienced in designing customized bearings according to customer’s different requests.. High precision, heavy load, long life, etc, every working condition will be considered in the bearing design to help increasing our customer’s productivity and reducing the operational cost.

Common Bearing Type:

Medical Equipment

Typical product: Stainless steel bearings

Medical equipment market is growing with the increasing population and health care expenditures. Modern medical equipment is not only used for disease detection but also prevention. There are continuous improving requirements on bearings for medical equipments, antibacterial, acid & alkali resistance, washable and non-toxic.

WD

Solution:

Through

the

cooperation

with

medical

equipment

manufacturers

and

end

users,

WD

understands

the

know-how

of

bearings.

We

use

high

quality

stainless

steel,

e.g.

SUS440

and

SUS304,

as

bearing

material

to

ensure

the

ability

of

anti

rust,

acid

and

alkali.

WD

also

uses

special

plastic

material

to

make

sure

the

antibacterial

ability,

as

well

as

food

grade

grease

to

guarantee

the

product

safety

and

non-toxic.

WD

solutions

help

our

customers

to

realize

reliable

diagnostics

and

treatments.

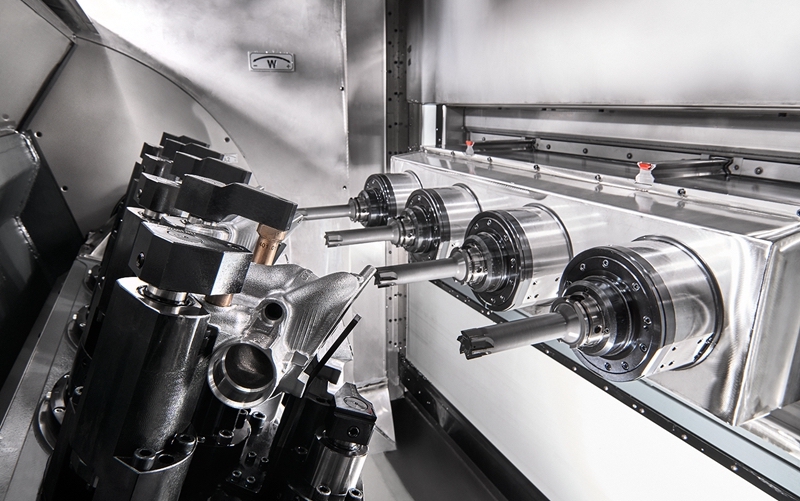

Machine Tools

Machine tool is playing an increasingly critical role in production efficiency and product quality. Bearings for machine tools must offer high reliability, high speed as well as high precision and easily to be maintained with long service life.

WD Solution:

WD is engaged to supply high quality bearings to machine tool manufacturers. The precision of WD angular contact ball bearings could reach P4S, which contribute to the high position accuracy of the machine tool. WD also offers a range of lubrication, sealing and material solutions (e.g. Kluber grease, special seals, ceramic balls) to prevent the harm from heat generation and extend the maintenance circle and service life. With WD solutions, customers could enhance the machine tool performance and also decrease the total cost.

Common Bearing Types:

Solar Tracker

Typical products: WD pillow blocks and rod ends

The world’s demand for solar energy is rapidly increasing. Generating as much power as possible while minimizing costs is critical. Solar tracker which is a device that orients solar panel toward the sun can increase solar panel’s efficiency by as much as 40%. Bearings for solar tracker must be reliable to maximum availability and productivity.

WD Solution:

WD produces a range of high quality bearings for solar trackers. For example, the easy-to-fit pillow blocks enable fast installation during replacement. WD also provides a range of bearing sealing and lubrication solutions to reduce the maintenance time and increase the service life. With WD solutions, customers can generate more power while reducing their total cost.

Thermo Power Plant

The electricity consumption continues increasing with the development of modern society. And the thermo power plant still plays an important role although the renewable energy is developing rapidly. Bearings are widely used in various thermo power plant equipments such as ventilator, exhauster, coal mill, etc. These bearings are facing extreme working conditions like dust, high temperature and heavy load.

WD

Solution:

Through

the

experience

of

our

close

partnership

with

thermo

power

plants,

WD

highly

understands

customer’s

needs

of

high

quality

and

reliability

bearings.

In

addition

to

a

wide

range

of

bearings,

WD

also

provides

excellent

engineering

services.

We

help

customer

to

analyze

the

failure

of

their

former

bearings,

and

provide

optimized

WD

bearing

solution

to

enhance

the

equipment

performance

and

reduce

the

total

cost.

Common Bearing Types:

Elevator

An elevator is a type of vertically transport equipment that efficiently moves people or goods between floors. The bearings used in elevators rotate forward and reverse frequently, and exposed to alternating stress. They must be reliable in order to keep goods and people safe.

WD Solution:

WD designs and manufactures series of bearings for elevator industry according to the requirement of low noise, high reliability and long life, like spherical roller bearings for hoisting machines, deep groove ball bearings for driving motors, cylindrical roller bearings for guiding wheels, etc. WD solutions help customers to meet their application and create more value for customers.

Common Bearing Type:

Industrial Fan

Industrial fans are machines whose primary function is to provide a flow of air or gas to various processes of many industries. The flow rates of these fans range from approximately 5 to 50000 m

Common Bearing Type:

Dyeing Machine

Typical product: WD Stainless Steel Bearing

Dyeing machine is used to add color to textile products like fibers and fabrics. The dyeing machine works in the environment of high temperature and damp, which makes the bearing easily get rusted and corrupted. The bearing failure will cause unplanned downtime which is costly in terms of lost productivity, and increase the labor cost in maintenance and replacement.

WD

Solution:

WD

has

rich

experience

in

designing

and

manufacturing

bearings

for

dyeing

machines.

WD

use

high

quality

stainless

steel

as

bearing

material,

which

prevent

the

bearing

get

rusted

from

damp

and

corrosive

environment.

Special

grease

and

bearing

sealing

solutions

enable

more

uptime.

All

these

advantages

help

WD

bearings

withstand

the

demanding

environment

and

create

more

value

for

our

customers.

Dental Drill

Typical product: WD dental drill bearings

Dental drill is a small, high speed drill used to remove decay and shape tooth structure or root canals. The bearing is a key part for dental drills. Modern dental drills can rotate at up to 400,000 rpm, which is really a challenge for the bearings.

WD design and manufacture bearings for different brand of dental drills, e.g. NSK, Siemens, Bein Air, and etc. WD use high quality stainless steel (9Cr18) or ceramic (Si3N4) as the bearing material, which enables the bearings to be washable and wearable. Special self-lubricated bearing cage is also used for WD dental drill bearings. With the WD manufacturing technology, the lifetime of WD dental drill bearings can reach up to 6 months. It will significantly reduce the cost of bearings and create more value for customers.

Encoder

Typical product: WD miniature ball bearings, e.g. MR series, 68X series.

The integration density of semiconductor products continues to increase. Smaller size and higher efficiency are always the development trend in this sector. These developments mean that more strict requirements are being made to the bearings used in semiconductor products.

WD

Solution:

WD

has

close

cooperation

with

semiconductor

manufacturers.

We

provide

bearings

without

exceptional

noise

to

ensure

the

silent

running

of

the

semiconductor

device.

Specially

designed

bearing

shields

are

used

to

prevent

the

grease

leaking,

which

may

cause

unexpected

stop

of

the

device.

Moreover,

we

understand

the

concern

about

environment

and

energy

saving,

WD

high

precision

bearings

have

less

internal

friction

and

can

work

with

smaller

starting

torque,

which

means

a

lower

power

consumption.

By

utilizing

WD’s

services

and

solutions,

the

total

product

cost

can

be

reduced

and

more

value

can

be

created

for

our

customers.

Fishing Rod

Typical product: WD stainless steel miniature ball bearings

Fishing rod is a long, flexible rod that used to catch fish. It is typically used in the sports of angling and competitive casting. For fishing sport, how to cast the lure to the accurate point is one of the key points. A good quality bearing for fishing rod plays an important role in casting. It also has to face water, especially seawater with salt, which is a challenge to the bearings’ anti rust ability.

WD Solution:

WD precision stainless steel miniature ball bearings for fishing rod are produced by high quality stainless steel material and also are filled with high quality grease to ensure the anti rust ability of the bearings. The high precision and special inner structure contribute to the smooth running and allow a smaller starting torque of the bearing, which support fisher to cast further, accurate, and avoid backlash. WD solution for fishing rod helps you to enjoy fishing and lower down the cost.

Food and Beverage

Typical Product: WD stainless steel bearing

The food and beverage industry plays an important role in our daily life. The bearings for this sector have to face various tough conditions, e.g. extreme temperatures, moist atmospheres, and regular wash-downs. At the same time, strict hygienic requirements and regulations must be followed to ensure food safety.

WD

Solution:

WD

works

closely

with

food

and

beverage

companies

and

we

understand

their

needs.

WD

bearings

using

high

quality

stainless

steel

or

even

ceramic

material

to

ensure

the

corrosion

protection.

Meanwhile,

food

grade

grease

is

used

to

ensure

the

food

safety

and

low

maintenance

requirements.

By

utilizing

WD’s

services

and

solutions,

higher

process

reliability

and

lower

cost

can

be

realized

without

putting

food

safety

at

risk.

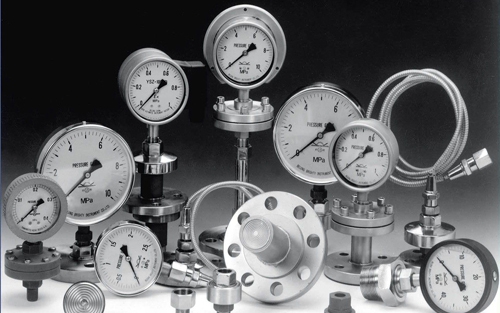

Instruments and Meter

Instruments and meters are used in various industries, e.g. the geodetic instrument, vertical collimator, etc. The bearings for instruments and meters do not bear heavy load, but they need to be reliable, long-lifetime and run quietly. The bearing friction and heat generation also need to be considered during design.

WD Solution:

WD manufactures precision deep groove ball bearings for instruments and meters. The precision of bearings can reach up to P5. The super fine finish enables the bearings’ low noise running (reach to Z4V4) and low starting torque. WD designs a smaller or even zero clearance to control the heat generation during operation. The special grease also allows free of maintenance. WD solutions bring reliability and create more value for our customers.

Common Bearing Type:

Metro Bogies

As an alternative to the crowded street transportation in cities, mass transit railways and metros are becoming ever more important. In this sector, product safety and reliability are always been emphasized. It also brings high quality requirement to the bearings for this sector.

WD solution:

WD plays an active role in designing and producing bearings for different bogies. We use high quality carbonized steel for bearing rings to ensure the product safety and reliability. Special grease is also used to meet the requirement of less maintenance. WD also provides engineering services according to customer’s application. Our high quality bearings have ensured customer’s safe, fast and reliable travel.

Common Bearing Type:

Home Appliance

Typical product: WD EMQ bearings, e.g. 62 series P5 Z4V4

Home appliance manufacturers are driven by the development trends of increased efficiency and lower energy consumption. Meanwhile, consumers always need the products with low noise, quiet running, long life, high quality and energy saving. The development of home appliance also brings higher quality requirements on the bearings.

WD

Solution:

WD

works

closely

with

home

appliance

manufacturers

and

our

bearing

solution

is

the

answer

to

satisfying

consumer’s

needs.

Thanks

to

WD’s

advanced

manufacturing

lines

and

test

equipments,

WD

EMQ

bearings

can

reach

the

quality

grade

highest

to

P5

ZV4,

which

means

a

significant

reduce

of

internal

friction,

noise

and

vibration

comparing

to

normal

products.

These

will

bring

great

benefit

to

enhance

the

product

performance

and

create

more

value

for

customers.

Money Counter

The money counter is widely used in banks, shopping malls, and even automated teller machines. The bearings for money counters do not take a heavy load or rotate fast, but they need the features of low noise, low vibration, and long life.

WD Solution:

Through the cooperation with manufacturers, WD produces a range of bearings for money counters, from needle roller bearings to precision deep groove ball bearings, or even flanged outer ring ball bearings. The noise & vibration level is Z3V3 or Z4V4, which best suits the money counters. WD solutions help customers to improve cost-efficiency and product reliability.

Common Bearing Type:

Paper Making Industry

With the rapid development of paper making industry, the paper machines are required to be more and more efficient, reliable and profitable. Bearings are used almost everywhere in paper machines such as forming roll, suction roll, press roll, guide roll, dryer roll, etc., where the working conditions are wet, dust, high temperature and with heavy load. Thus the bearing quality is one of the key factors for the outstanding performance for paper machines.

WD

Solution:

WD

has

close

cooperation

with

manufacturers

in

paper

making

industry.

We

understand

the

unique

operational

conditions

of

different

paper

machines.

We

design

and

supply

a

variety

of

customized

bearing

solutions

in

order

to

promote

production

efficiency

and

machine

reliability

while

also

taking

the

cost

saving

into

consideration.

Common Bearing Type:

Printing Machine

Printing machines are required to output sharp printing quality and high productivity. The high quality performance of printing machines is highly related to the bearings used. The bearings for printing rollers usually do not carry heavy load or high rotation speed, but one of the greatest enemies of these bearings is the printing ink. It will cause the failure of the machine and bring a great loss.

WD Solution:

WD has close partnership with printing machine manufactures. We do different tests to analyze the performance of bearings and printing machines with manufacturers, and then to improve our product quality. WD bearings provide excellent sealing performance, which can prevent the printing ink, who will cause the grease failure or unexpected stop of the machine, from infiltrating through bearing seals. By our accumulated applications knowledge, WD creates more value for our customers.

Common Bearing Type:

Power Tool

The manufacturers of power tools are driven by the customer needs of a compact, low noise, and efficient products. These needs also bring higher requirements to the bearings used in power tools.

WD Solution:

WD has close partnership with power tool manufacturers. We provide various bearings for different customer applications. For example, high precision deep groove ball bearings can significantly reduce the noise of power tools; Needle roller bearings can be used when assembly space is limited in a compact tool. And if this solution does not suffice the application, we will jointly find a solution that is matched to your requirements.

Common Bearing Type:

Shock Absorber

A shock absorber is a type of dashpot which is designed to smooth out or damp shock impulse. It is widely used in different vehicles, from passenger cars to racing cars. The bearing for shock absorber must have great load-carrying capacity as well as lightweight. It also needs to be well self-lubricated to take the impact load and reduce the maintenance cost.

WD Solution:

WD is an expert in designing and manufacturing bearings for shock absorbers. We use high-quality alloy steel as bearing material, which leads the bearing to an excellent load-carrying capacity. PTFE layer or special engineering plastic is used as a self-lubricant to reduce friction. The WD solution for a shock absorber is safe, reliable, and cost-effective.

Common Bearing Type:

Skating

Skating is very popular among young people. It is also a kind of extreme sport. The most common bearings used for skateboard are 608-ZZ and 608-2RS. But it also has a high requirement for these bearings to ensure good performance of skating.

WD

Solution:

WD

provides

various

bearings

for

the

skateboard.

The

bearing

precision

ranges

from

ABEC

1

to

ABEC

7

to

meet

different

requirements.

WD

even

uses

ceramic

as

the

material

of

bearing

balls

to

bring

excellent

performance

for

the

skateboard.

Personalized

colors

are

available

for

seal

rings

to

satisfy

the

individual

needs

of

skaters.

WD

provides

tailored

solutions

for

different

customers

and

helps

them

enjoy

skating.

Common Bearing Type:

Retractable Roof

Retractable roof is used in many stadiums, in which the roof can readily be mechanically deployed from some retracted or open position into a closed or extended position that completely covers the field of play and spectator areas. With the retractable roof, the stadium allows both indoor and outdoor activities when the weather is favorable. The track rollers which support the retractable roof do not move fast, but carry heavy load. Meanwhile, there is strict requirement for products’ safety and lifetime.

WD Solution:

WD designs and supplies various track rollers for the retractable roofs all over the world. Special alloy steel is used for the bearings to ensure the high load carrying capacity and the product reliability. Moreover, it is also designed to prevent corrosion from the variable outdoor weather. By utilizing WD solution, the retractable roof can be operated under safety and reliability at the same time with cost saving.

Common Bearing Type:

Straightening Machine

Typical product: WD XGKHB series back-up roll bearings

The straightening machines are the equipment that straightens the steel tubes, plates, bars, etc. There are a number of rollers in each machine. The rollers keep pressing, bending, extruding, and finally straightening the material. This equipment is constantly exposed to extreme working conditions, and carry the high non-uniform load through the continuous non-stop working period.

WD

Solution:

WD

engineering

experts

keep

close

contact

with

steel

producers.

We

understand

the

customer

needs

for

reliable

products

and

cost-saving

in

this

highly

competitive

industry.

Therefore,

WD

provides

bearing

solutions-oriented

by

the

actual

applications,

and

help

customer

to

replace

the

low

cost-effective

products.

The

precision

of

WD

straightening

machine

bearings

can

be

reached

to

P5

and

P4,

and

we

use

special

material

and

heat

treatment

to

guarantee

bearing’s

normal

performance

even

in

tough

working

conditions

in

order

to

improve

the

lifetime.

Textile Machine

Textile machine is used to make textiles, e.g. knit fabrics, weave yarn, and etc. The bearings for textile machine usually do not bear heavy load. However, the working condition makes the bearings easily rusted, corrupted or worn out.. The bearing failure will cause unplanned downtime which is costly in terms of lost productivity, and increase the labor cost in maintenance and replacement.

WD Solution:

WD has rich experience in designing and manufacturing bearings for textile machines. We have designed plastic rod end bearings especially for textile machines. The advantages of these bearings are anti rust and corrosion, self-lubricated, light weighted and with low noise as well. It also reduces the maintenance time and creates more value for customers.

Common Bearing Type:

Theme Park

Bearings are used in different facilities in a theme park, for example, precision ball bearings for roller coasters, slewing bearings for carousels, and etc. These bearings usually work day and night and must be reliable. Any bearing failure will bring danger to people and cause unexpected accidents.

WD Solution:

Through the cooperation with manufacturers and users of amusement facilities, WD understands the know-how of the bearings. WD implements strict inspection of the raw material, to avoid failure from the source. We also set up a metallographic lab to inspect the microstructure of the bearings to ensure product safety and a long lifetime.

Common Bearing Type:

Ticket Machine

Ticket machine is a vending machine that prints tickets. For instance, ticket machines dispense train tickets at subway stations and parking tickets at parking lots. The bearings for ticket machines do not bear heavy load or rotate fast, but they need to run quietly and have long life.

WD

Solution:

WD

produces

precision

miniature

ball

bearings

for

ticket

machines.

The

bearing

noise

and

vibration

reach

to

Z3V3,

which

ensures

the

quiet

running

of

the

machines.

WD

also

produces

stainless

steel

bearings

for

outdoor

ticket

machines.

WD

solutions

help

customer

to

replace

top

brand

bearings

and

significantly

save

the

cost

on

bearings.

Common Bearing Type:

Vibrating Screen

Vibrating screen is used to separate bulk materials in a mixture of different sized particles, for example sand, crushed rock, ore, and etc. It is widely used in the industry of mining and metallurgy, where the operational environment is tough for the bearings. Heavy load, dust and dirt, these conditions make it difficult to keep the good performance of bearings.

WD Solution:

Through the cooperation with manufacturers and end users, WD has much know-how about bearing design for vibrating screen. WD spherical roller bearings are available in CA and CC cage types, even E types. High precision rollers for bearings, special design in product curvature, super fine finish for the raceway, all these advantages contribute to the control of heat generation under 45℃. WD not only provides bearings, but also solutions for our customers to achieve their goals.