Combined Bearings

Built like a tank to perform under tremendous axial and radial loads. Combined bearings feature a radial bearing coupled with an integrated axial bearing that allows for extreme versatility in any application.

The WD Edge:

- 65% of global usage manufactured in-house at WD

- WD’s most popular privately-labeled product

- Longer life with 99.98% VIM-VAR steel

- Maximum flexibility and load distribution with customizable outer ring profile

- Fully customizable optional mounted flange plate including black oxide coating

- Match load requirements with needles ; single, double, or full-complement rollers

- Reduced design and production cost with minimal assembly requirements

- Maintain and re-lubricate without disassembly

- Inner rings made of GCr15 equivalent to AISI 52100

- Impact-resistant chromium-nickel alloy outer rings case-hardened to 64HRC

- Available with CorroFree720 corrosion-resistant surface treatment

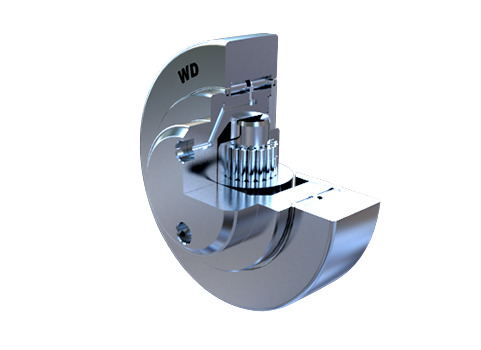

Manufactured In-House and Fully Customizable

Combined Bearing Strength and Endurance:

Applications requiring heavy radial and axial loads going beyond traditional mast guide and cam follower capabilities need a combination bearing. Operating under heavy loads, combined axial radial bearings are often used in conjunction with horizontal, vertical, cantilevered, or telescopic motion such as with forklift machinery.

Strong and simple design, customizable profiles, and easily exchangeable components make combined bearings a robust and economical option for many applications.

Quick Links

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

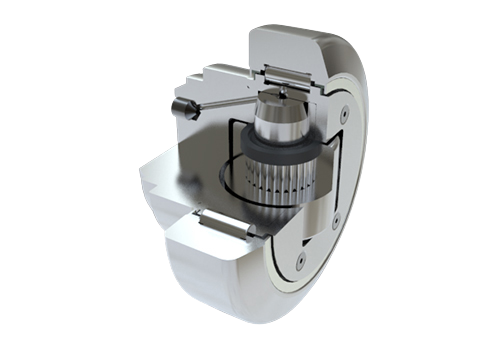

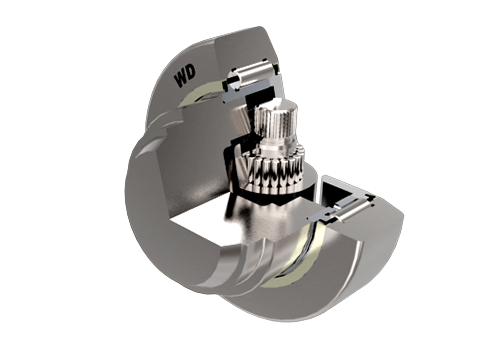

Combined Bearings: Components and Uses

Combination bearings are composed of three distinct components:

- Radial Bearing : A profiled outer ring used for guided rolling contact along a steel rail or channel

- Axial Bearing : This integrated roller guides and maintains the position of the bearing along its track while offering axial load resistance.

- Stub Axle (Shaft) : This central shaft stabilizes the bearing and offers simple relubrication and assembly.

Strong and simple design, customizable profiles, and easily exchangeable components make combined bearings a robust and economical option for many applications.

These high-load combined bearings offer the flexibility in handling axial and radial loads in one or both directions simultaneously. With so many rolling elements, the carrying capacity of combined bearings are some of the highest available in any bearing type.

In applications where space is tight, combined bearings offer a lower cross-section to maximize the available space. Combined bearings from WD Bearing Group have an optimized (customizable) profile and can be welded within the mounting plate to eliminate the need to dismantle the entire assembly for any reason.

Common Industries & Applications

Industries

Refuse, Automotive, Oil & Gas, Tool & Die Manufacturing, Medical, Packaging, Material Handling, Marine, Pulp and Paper, and General Manufacturing

Applications

Refuse trucks, forklifts, telehandlers, sorting and transfer systems, cranes and hoists, palletizers/depalletizers, high load lifts, cranes and hoists, horizontal and vertical feed units, shrink-wrappers, overhead conveyors, and automotive lifts

Forklifts

Telescopic Refuse Arms

Automotive Lifts

The Social Influence Behind Bearing Choice

It is paramount to the successful operation of any OEM to carefully consider the bearings they choose. When generating motion is essentially the standard of success, what does it say when bearings are overlooked? In many ways the decisions made on bearings influence the overall performance and lifetime of all applications that utilize combined bearings and ultimately affect customer relationships, revenue, and perception of brand.

All bearings, including combined bearings, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

We have a robust selection of combined bearings to fit any application you’re working with. And, of course, if you need something special, we’ve got your back there, too.

Contact Us Now

We believe in quick and efficient communication. For more information, feel free to:

- Use our Live Chat feature to chat with us right now . No robots – just us! Simply click the chat icon on the bottom right of your screen.

- Call or email our knowledgeable, non-commision sales team.

- Send us a message using our quick and easy contact form.

WD Bearing Group produces the whole range of combined bearings, both standard and non-standard designs. Customized combined bearings are available to fit your application as well as a risk-free application review where we provide our engineering recommendations to improve your application or reduce your operating costs.Combined Bearings

Celebrating 25 Years Of Bearing Experience In 2025

Precision Bearings Manufactured Entirely In-House.

"WD is the bearing manufacturer I wish I found ages ago."

Manufacturing and Quality Control

We source our high-quality 99.98% VIM-VAR steel and move it directly into our production facility where grinding, turning, heat-treating, assembly, and washing occurs. Our quality assurance and control teams constantly evaluate our product until they ship to the customer.

Engineering and Local Support

WD Bearing manufacturing headquarters is a 20,000 m² facility with a dedicated 140 m² quality and inspection room. Our engineering labs in Europe and North America extend our quality control, service, and sales to the entire world. Our global presence ensures that our customers receive local support from our dedicated sales and service teams, regardless of their location worldwide.

Experience and Partnerships

WD Bearing Group has crafted a team with hundreds of years of engineering experience collectively. Our engineers have developed applications used by NASA on the Mars rover, the construction of the World Trade Center, and numerous bearing-specific applications with popular OEMs around the world.

We're ready to help.

Let's start something great together.

Upgrade your application. Save costs and improve performance.